200 KLD CAMUS-SBT Based STP at Vadodara Airport

|

Scale of service |

Individual(Airport) |

Area of installation (Sqm) |

450 sqm |

|

Year of Installation |

Sept. 2016 |

Capital cost |

Rs. 116 Lakh |

|

Location |

Vadodara Airport |

Operational & Maintenance cost |

Rs. 18 Lakh |

|

Funding Agency |

Airport Authority of India |

Design Capacity |

200 KLD |

|

The STP was proposed to treat the sewage generated considering the average passenger’s footfall per day is 5000 people and also for the Airport Staff. |

|

|

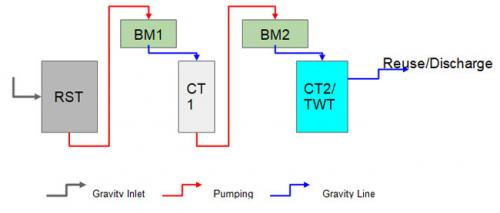

RST:- Raw Sewage Tank, CT1:- Collection Tank 1, CT2:- Collection Tank 2, TWT:- Treated Water Tank, BM1:- Bio Mound 1, BM2:- Bio Mound 2 The sewage from the facility after Preliminary Screening gets collected to Raw Sewage Tank (RST) for collection and equalization. The raw water is pumped to Bio Mound 1 (BM1) via the piping network in BM1 which enables equal distribution of sewage throughout the reactor surface area. The sewage distributed in BM1 gets trickled down by gravity in Collection Tank 1 (CT1). Similarly, the water in CT1 gets pumped to Bio Mound 2 (BM2) further treated and collected in Collection Tank 2 (CT2). The water in the CT2 Tank is the treated water and hence CT2 is named as Treated Water Tank (TWT) also. |

|

|

Since three year of Operation & Maintenance, Plant has been able to achieve sustained results with treatment efficiency in terms of TSS (>85%), BOD (>85%) & COD (>85%). The treated water is odour-free and colour free. |

|

|

Senior Manager (Engg-Civil) For Vision Earthcare Pvt. Ltd. Dr Chandrashekar Shankar |

|

Share this article