SBT and CAMuS-SBT TECHNOLOGY (ontinuous Advanced Multiscale System using Soil Bio Technology)

CAMuS-SBT (C-SBT or Continuous Advanced Multistage System – Soil Biotechnology) is an advanced version of the Basic Soil Bio Technology (SBT) process for waste rejuvenation. CAMUS-SBT is a unique innovation to treat sewage water using terrestrial ecology leveraging the insights derived from the carbon cycle which reveals that the energy required to live in a terrestrial environment is at least 300 times less than the energy needed to live in an aquatic environment. CAMUS-SBT offers consistent treated water quality in much less space and without much energy consumption. CAMuS-SBT uses special highly active catalysts and local manufactured media so occupies a small footprint compared to SBT. CAMUS-SBT is an advanced form of basic SBT technology.

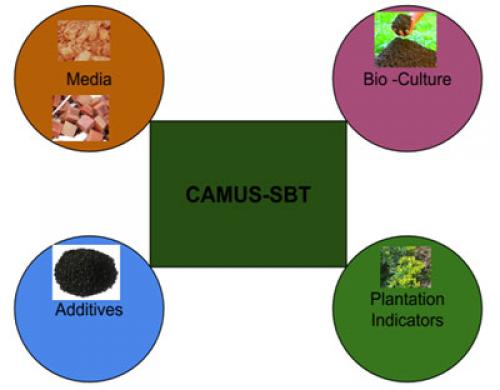

Components of SBT / CAMUS-SBT: Media, Culture, Additives and Plantation

|

Characteristics |

CAMUS TECHNOLOGY |

SBT TECHNOLOGY |

|

Area required / MLD sewage |

400 - 600 sqm / MLD |

1000-3000 sqm / MLD |

|

Process Power /ML |

80-120 KWHr |

80-100 KWHr |

|

Manpower/MLD |

2 |

10 |

|

Design Criteria |

BOD<10 mg/L, TSS<10mg/L, COD<50mg/l |

|

|

Equipments and Processes |

||

|

Grit Removal |

Yes |

No |

|

Fine Screen |

Yes |

Optional |

|

Automatic TSS Separation |

Yes |

No |

|

Automatic Sludge Processing |

Yes |

No |

|

BioGas Generation |

Optional |

No |

|

BioMound Maintenance |

Minimal |

Constant Sludge Removal |

|

Biological Nitrogen Removal |

Yes (In 2 Stage Design) |

No |

|

Phosphate Removal |

Yes (In Primary Settling) |

Partial |

|

Heavy Metal Removal |

Yes |

No |

|

Media Types |

Natural or Artificial |

Natural only |

|

Water on Surface of BioMound |

Invisible/Camouflage |

Sludge causes flooding |

|

Bio Media Design |

Deep bed (3.0m+) |

Shallow bed (~1.5m) |

|

Media Quantity |

1.1-1.6 cu.m/KLD |

3 cu.m/KLD |

|

Plant Scale |

Large (~0.5-50 MLD) |

Small (0.1-0.5 MLD) |

|

Commercial Viability |

Excellent |

Poor at large scales |

|

Water Quality Control |

Via Unit Process Sizing, Dosing of additives as required |

Via Water Recycling |

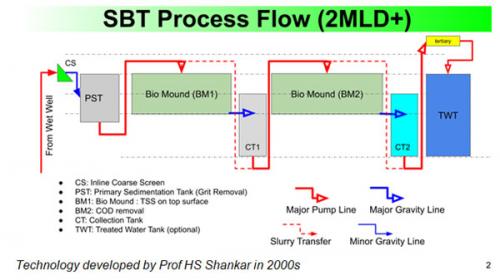

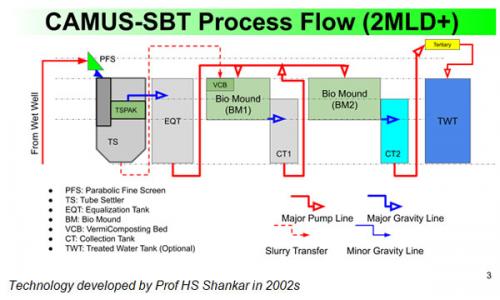

Process Flow mechanism:

The CAMUS-SBT has two process flows based on the volumetric loading (KLD) in the plant viz.,:-

1. For Q < 500 KLD,

The sewage from the facility after Pre Liminary Screening gets collected to Raw Sewage Tank (RST) for collection and equalization. The raw water is been pumped to Bio Mound 1 (BM1) via the piping network in BM1 which enables equal distribution of sewage throughout the reactor surface area. The sewage distributed in BM1 gets trickled down by gravity in Collection Tank 1 (CT1). Similarly, the water in CT1 gets pumped to Bio Mound 2 (BM2) which gets treated and collected in Collection Tank 2 (CT2). The water in the CT2 Tank is the treated water nad hence CT2 is named as Treated Water Tank (TWT) also.

2. For Q> 500 KLD

After initial fine screening and de gritting the raw water is passed through a tube settler (with flocculation and coagulation as necessary) wherein the large suspended solids (greater than 100microns) are settled out 2) The clarified sewage is pumped on first CAMUS-SBT®️ Bio Mound (BM1) where it percolates through a specially designed bio media. The percolation of BM1 is passed to Second Bioreactor & through percolation water is treated. The treated water is discharged/reused by disinfection with help of disinfectant (Chlorine/Ozone). The sludge in TS is pumped to BM3 for Sludge Drying & disposal in the form of cakes.

Salient Features:

- No mechanical aeration

- Low power consumption

- All green process

- No moving parts

- No bio-sludge formation

- Efficient removal of pollution

- Garden like ambience

- One time media installation

- Long life

- Unskilled personnel sufficient to operate

- Works on zero load to full load without any downtime due to soil ecology

Name :- Dr Chandrashekar Shankar

Phone No :- +91 9769605447

Email Id :- contactus@visionearthcare.com

Address: :- Vision Earthcare Pvt. Ltd.202/4, Mandakini, Cosmopolitan CHS, Plot17, Sec19A, Nerul (E) 400706

Website :- http://www.visionearthcare.com

Share this article